About TMP

With a legacy spanning over

70 years

TMP Technologies is a vertically integrated contract manufacturer capable of taking ideas from your napkin all the way to highly automated production including any and every step along the way.

We are organized as four independent divisions that share corporate leadership, resources, and capabilities.

TMP operates within 390,000 sq-ft of manufacturing space located in the Buffalo, NY area. We are positioned with the infrastructure and land for future growth.

Early Beginnings

From its inception, TMP Technologies has been fueled by imagination and innovation. The company’s founders initially introduced a patented clothesline system. Building on this success, they later innovated a manufacturing technique for producing consumer foam and sponge products, such as a patented floor mop. In these formative years, the TMP team relied on their adept design and fabrication abilities to construct their production machinery.

Expansion and Development

The 1960s marked a period of substantial growth and expansion for TMP Technologies. The pivotal moment came with the creation and patenting of the world’s foremost liquid shoe polish applicator. This achievement along with future innovations, solidified TMP Technologies’ reputation as THE APPLICATOR COMPANY™.

As the business flourished, TMP Technologies acquired Hallmark Plastics to streamline its manufacturing process. Concurrently, the company invested in a single press injection rubber molder, which eventually evolved into one of its present affiliates, Advanced Rubber Products.

In 1996 TMP expanded its capabilities by acquiring the Foam Sciences division, adding premium hydrophilic polyurethane foam to its product portfolio. Today, Foam Sciences is recognized as an industry leader in hydrophilic polyurethane foam manufacturing, serving critical applications in medical devices and cleanroom environments.

TRS Packaging — TMP’s fourth division was established in 2003 to serve a major consumer products partner. Since 2003, TRS has pursued several strategic growth projects to meet rising demand and scale operations. TRS recently completed a 290,000‑square‑foot manufacturing plant, substantially enhancing both production throughput and distribution efficiency.

Sustained Innovation

The essence of innovation endures at TMP Technologies. From initial idea conception to product design, manufacturing, packaging, and labeling, we collaborate with entrepreneurs to bring their foam products and applications to the market.

Today, TMP Technologies is esteemed for its top-notch custom foam applicators, consumer foam and sponge cleaning products, and hydrophilic medical & clean room foam products. The company is dedicated to continuing its legacy of serving Fortune 500 companies, OEM’s and other large-volume enterprises.

Design Engineering

Our in-house Engineering Team can assist with custom product design, process development, and highly automated equipment design all with the end goal of producing your custom applicator.

We make use of state-of-the-art design tools including 3D CAD, CNC machining, and 3D printing technologies.

Our prototyping capabilities allow us to quickly provide conceptual samples, fully functional prototypes, and production quality sales samples.

TRS Packaging

TRS Packaging, a contract manufacturing and packaging facility dedicated to producing consumer cleaning products.

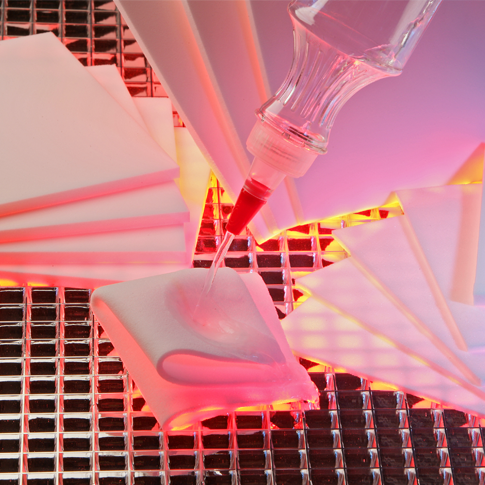

Foam Sciences

Foam Sciences, a leading producer of hydrophilic foam formulations and materials for a wide variety of industries including medical, clean room and labratory. The company specializes in Capu-Cell™, a proprietary hydrophilic foam formulation.

Advanced Rubber Products

ARP, a contract manufacturer specializing in rubber molded components for a variety of uses.

TMP Technologies

contact us

If you have questions regarding a product or capability, please inquire. We work hand-in-hand with your design and development team to efficiently bring prototypes, product designs or new ideas from conception to production.

Please contact TMP if you have any questions or would like to learn more about our services. We’d love to hear from you.

"*" indicates required fields